- Industries

- Solutions

- About SEKISUI S-LEC

- Downloads

- Contact Us

- What’s NEW

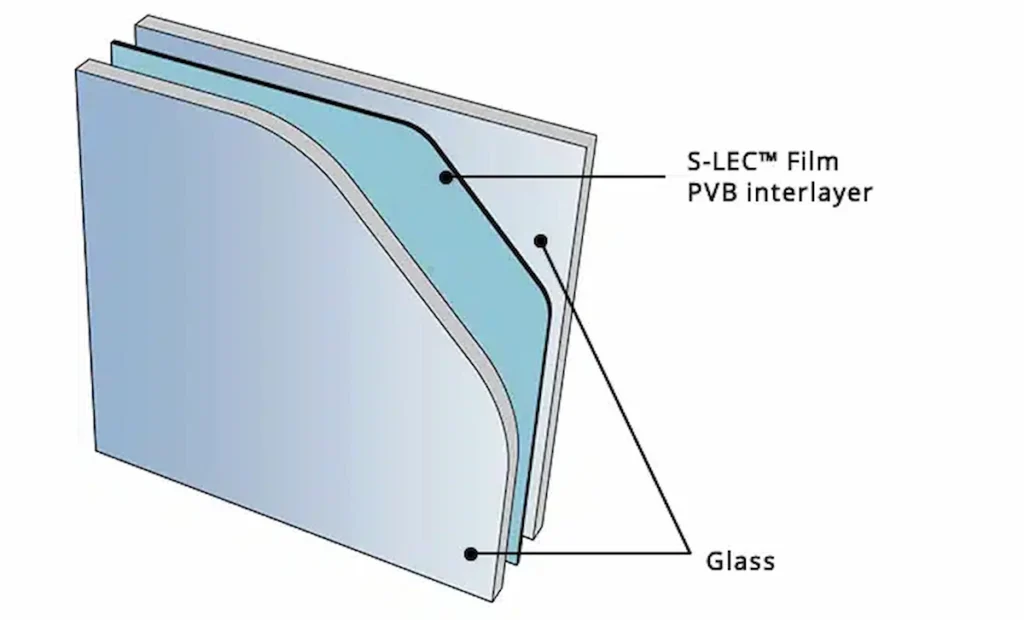

Laminated glass is a type of safety glass made by laminating an interlayer film between two panes of glass.

There are various types of interlayers, including EVA (ethylene vinyl acetate), urethane, and PVB (polyvinyl butyral). Laminated glass made with PVB interlayer is characterized by its high adhesion to glass, penetration resistance, and impact resistance compared to other materials.

Laminated glass with PVB interlayer is widely used in automotive windshields, side door windows, and architectural glass, where safety and security are required due to its shatterproof function.

SEKISUI S-LEC is a global supplier of PVB interlayers for laminated glass. Our S-LEC™ films for laminated glass provide a variety of solutions for automotive and architectural needs.

Tempered glass is another type of safety glass that is strengthened by heat-treating and cooling the entire glass to make it stronger and more resistant to breakage. It differs significantly from laminated glass as tempered glass does not provide shatterproof performance when glass gets broken.

Window films are also used to prevent shattering of glass. However, they need to be replaced when their function deteriorates due to ultraviolet rays, temperatures, condensation, and other factors.

Laminated glass has a PVB interlayer between two glass panes, which prevents shards of glass from shattering on impact and provides high penetrating resistance, making it useful for automobile and building safety and crime prevention. Since these functions are inside the glass, unlike window films, it has high durability.

PVB interlayer can provide various functions and values from SEKISUI S-LEC’s technologies, such as:

Using PVB interlayer with these functions and designs in laminated glass can add value beyond safety and security.

Using laminated glass for windshields where safety and security are required is mandatory in almost all countries, such as the U.S., Europe and Japan.

Laminated glass not only enhances automotive safety, but its applications are expanding beyond windshields to include side door glass and panoramic roofs, as it is required to provide a variety of functions such as UV blocking, visible light control, solar control, sound acoustic, and switchable.

The role of laminated glass is expanding in terms of comfort and design.

Large glass has become a trend in contemporary architecture to create attractive and bright spaces. Glass is also used in doors, stairs, and partitions to create the appearance of open and spacious indoor spaces.

Because of this trend, laminated glass is widely used in architectural glass facades, curtain walls, glass partitions, and other applications, adding value not only in terms of safety, security, and transparency but also in terms of solar and sound insulation as well as design features defining the character of a building.

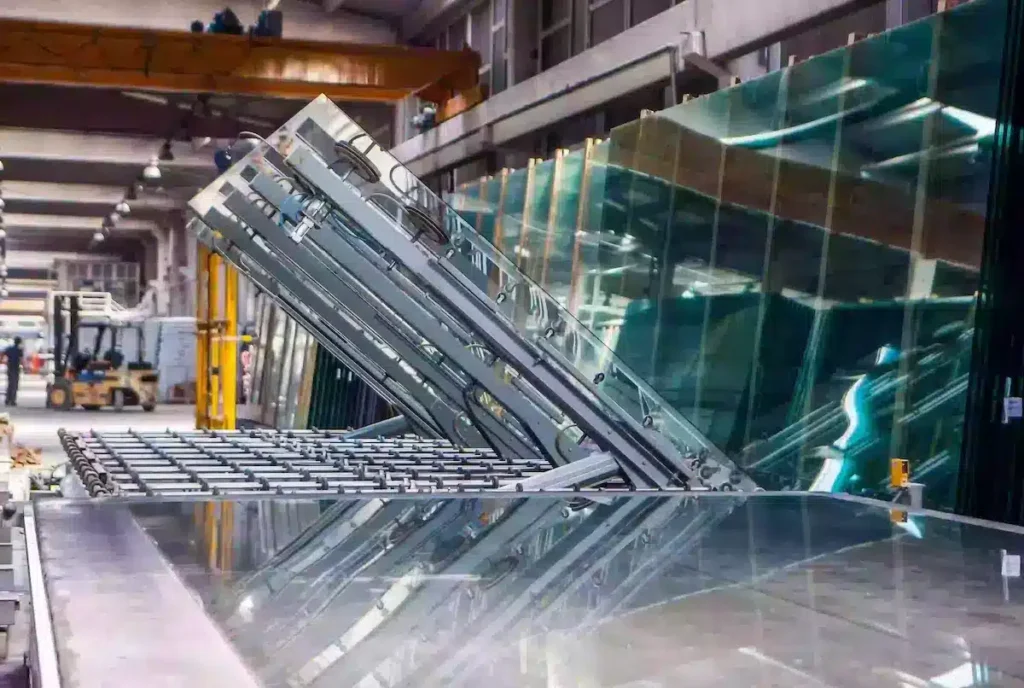

A typical PVB laminated glass production process is as follows. Two sheets of glass are cut to size and laminated with a PVB interlayer between them. The glass and interlayer are temporarily laminated by applying heat and de-airing. Next, the glass is placed in an autoclave, where high temperature and pressure are applied to bond the glass and PVB interlayer completely.

The glass and PVB interlayer are then formed as one piece of glass, resulting in a laminated glass product that is more shatterproof and has superior penetration resistance than a single sheet of glass.

S-LEC™ Film, SEKISUI S-LEC’s PVB interlayer for laminated glass, offers a variety of solutions for automotive and architecture glass, including safety, security, UV blocking, design, solar control and sound acoustic.

S-LEC™ films are currently available in a wide range of standard colours and custom colour options with multiple Tvis (Visible Light Transmittance) to optimize various glass combinations according to a vehicle’s concept.

In addition, our line-up also consists of wide gradient colour that transitions from 2% to >70% Tvis(Visible Light Transmittance). By adapting to a windshield or rear window, it creates a feeling of openness and beauty through smooth gradation, providing an advanced design for automotive glass.

Laminated glass with S-LEC™ Solar Control Film blocks infrared and UV (ultraviolet) rays but allows visible light rays for optical clarity without blocking the electromagnetic transmissions necessary for mobile phone and sensor communication. Solar absorbing glass realized by S-LEC™ Solar Control Film protects people because the cabin space stays cooler, so your skin does not burn.

Experience a comfortable, efficient, connected, and safe environment.

S-LEC™ Sound Acoustic Film can be used to block outside noise from the outside world such as traffic, wind, and other disturbing sounds to tune out distractions for people to create a peaceful, quiet experience.

You can combine acoustic quality with other functions or designs, such as solar protection or privacy colours, by incorporating soundproof film and other technologies into the laminated glass.

There is an increasing demand for glass that can protect against UV due to the many health and beauty concerns of exposure to sunlight. These concerns can span from young adults worrying about premature ageing from sun exposure to parents wishing to protect young children with vulnerable skin facing a higher risk of sunburn.

Laminated glass with S-LEC™ Premium UV Blocking Film protects the skin for those who need UV protection to reduce health risks.