- Industries

- Solutions

- About SEKISUI S-LEC

- Downloads

- Contact Us

- What’s NEW

Automakers have developed a variety of features to differentiate their vehicles from other brands. In particular, the power unit is used by each company to differentiate from other car manufacturers using each company’s knowledge and skills.

Electric vehicles generally require 40% fewer parts in comparison to conventional gasoline vehicles. Because electric vehicles no longer require engine control units, transmissions, spark plugs, and other components, EVs are relatively easier to assemble due to the simplicity of the vehicle structure.

This however has made it more difficult to differentiate cars from one another and to identify their unique characteristics. This is why now parallelly car manufacturers try to differentiate themselves from their competitors via other methods, such as by enhancing the automotive glass part of the exterior.

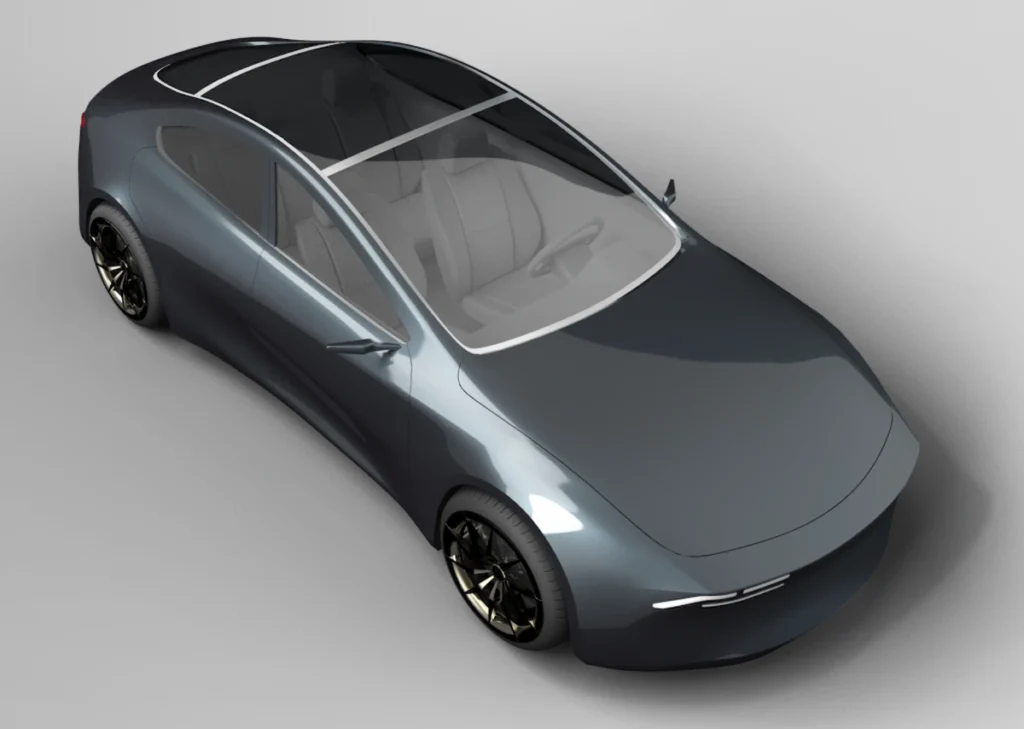

In the exterior design of electric vehicles (EV), the windshield, roof glass and rear window are increasingly being designed to look like one large integrated glass panel. While this advanced design makes a vehicle look more stylish, it also means that due to the increase in the size of the glass, more sunlight can enter the interior.

It is important to manage the heat entering the vehicle – not only for the comfort of the driver and passengers – but especially because this influences the driving range of the vehicle indirectly when people make use of the air conditioning more often.

Automotive glass is required to meet both the aesthetic and functional demands of electric vehicles. By improving the functionality of the glass, the car can be kept cool, and the driving range can be improved.

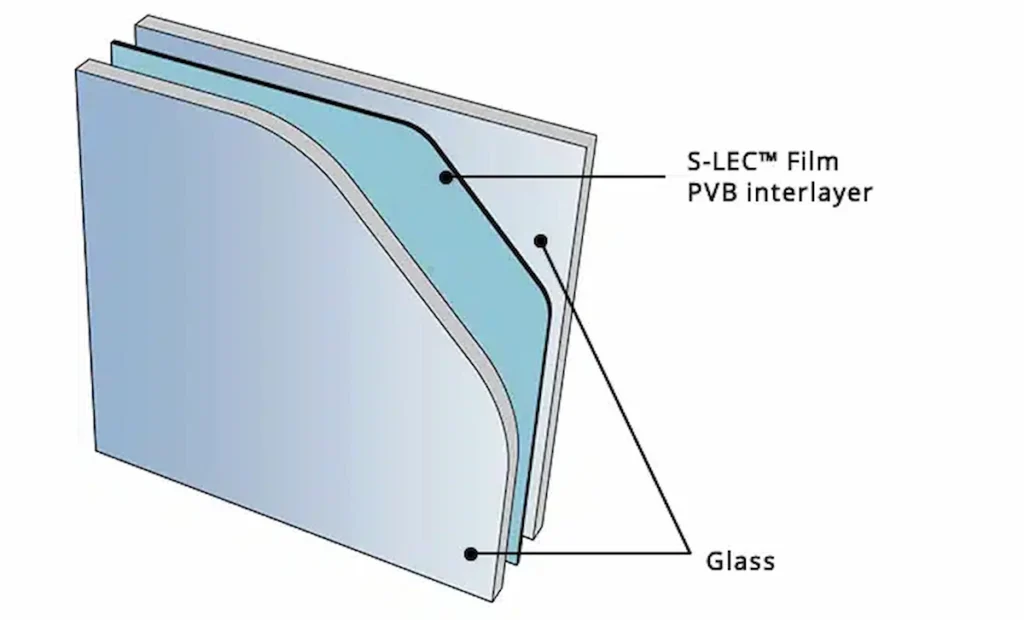

Because of its shatterproof function, PVB interlayer for laminated glass is used in many ways where safety and security are required, such as automobile windshields and side door windows. The role of glass in terms of comfort, design, safety, and security is expanding as more bright and open spaces are required today. PVB Interlayer is attracting attention as a technology that can enhance the possibilities of glass.

SEKISUI S-LEC supports the development of advanced EVs with “NEW glass” that goes beyond meeting safety standards. We offer a variety of advanced interlayers for laminated automotive glass that go beyond conventional functions.

S-LEC™ PVB Interlayer Film for laminated glass can be customized with a wide variety of features. While maintaining shatterproof functionality that meets conventional safety standards, S-LEC™ Film improves user comfort with functions such as heat reduction, sound insulation, and ultraviolet ray blocking. The wide range of available colours allows for no compromise in design, providing the user with a one-rank higher experience.

Automotive laminated glass with S-LEC™ PVB interlayer film will also make a significant contribution to electrification in the automotive industry.

Energy saving is considered very important for EVs, to make sure limited battery capacity is used for other functionalities not related to driving.

S-LEC™ Solar Control Film can reduce the temperature rise inside the vehicle, reducing the need for switching on the air conditioning to save the amount of energy consumed by the AC unit in electric vehicles. Through vehicle testing, SEKISUI S-LEC has confirmed up to 20% of energy can be saved.

Download the brochure for more information.

Panoramic roof

Panoramic roofEspecially for electric vehicles, roof glass is increasing in size (panoramic roofs) which requires diverse solutions such as design and sound insulation and it’s becoming more important to control the amount of sunlight entering a vehicle. Excessive exposure to sunlight can create a hot and uncomfortable experience.

To solve this problem, our Dark Colour Series offers a wide range of colours with visible light transmittance from 2% to 35%. You can choose the most suitable colour to optimize various glass combinations according to a vehicle’s requirements.

The design of a car is the second most important factor to make the purchase after the price. Some people even become fans of a certain brand or car model based on the design of the car.

To enhance design possibilities for the automotive industry, SEKISUI S-LEC provides solutions to expand the possibilities and options. Nowadays, there are many specific technical requirements such as:

At SEKISUI S-LEC we try to work together with designers and engineers alike by incorporating their designs while meeting the technical requirements for laminated glass.

Energy saving is considered very important for EVs, to make sure limited battery capacity is used for other functionalities not related to driving.

S-LEC™ Solar Control Film can reduce the temperature rise inside the vehicle, reducing the need for switching on the air conditioning to save the amount of energy consumed by the AC unit in electric vehicles. Through vehicle testing, SEKISUI S-LEC has confirmed up to 20% of energy can be saved.

Download the brochure for more information.

For modern vehicles introduced in the market recently, more glass is used to create an open, living room impression. The auto glass is designed to look like one large piece, rather than separated portions. It’s crafted to appear as one extended piece of glass that runs from the back to the roof down to the front of the windshield.

S-LEC™ Wide Gradient Film has a lineup of multiple types of designs with different gradation widths and visible light transmittance of the colour portion. The appropriate combination of products can be selected according to the desired design. Customization of design is also possible based on inquiry.

In comparison to traditional vehicles, noise that was previously hidden by the noise from the engine such as traffic noise, wind noise, and raindrop noise can be more noticeably heard. These noise distractions have a significant impact on the driver’s concentration and passenger comfort. In addition, the noise generated from the inverter of the EV also enhances the need for better sound insulation in EVs.

Our NEW acoustic grade, SV grade, is developed to improve damping performance and significantly reduce vibration noise caused by wind knocking on the glass. Using an acoustic interlayer film for the side windows, in addition to the windshield can greatly enhance the cabin’s quietness and comfort, making the electric drive a unique, luxurious experience.

There is an increasing demand for automotive glass that can protect against UV due to the many health and beauty concerns of exposure to sunlight during a long drive for both the driver and passengers alike. These concerns can span from young adults worrying about premature ageing from sun exposure to parents wishing to protect young children with vulnerable skin facing a higher risk of sunburn.

S-LEC™ Premium UV Blocking Film protects the skin for those who need UV protection to reduce health risks.