- Industries

- Solutions

- About SEKISUI S-LEC

- Downloads

- Contact Us

- Subscribe

The key challenges car manufacturers face today are to reduce engine, road noise and wind noise to enhance cabin comfort.

As CO2 reductions for a better environment is a continuous item on the global vehicle development agenda, the shift to EVs is rapidly expanding. As a result, noise sources previously hidden by the noise from the engine become recognizable, and glass windows are required to provide even better sound insulation performance.

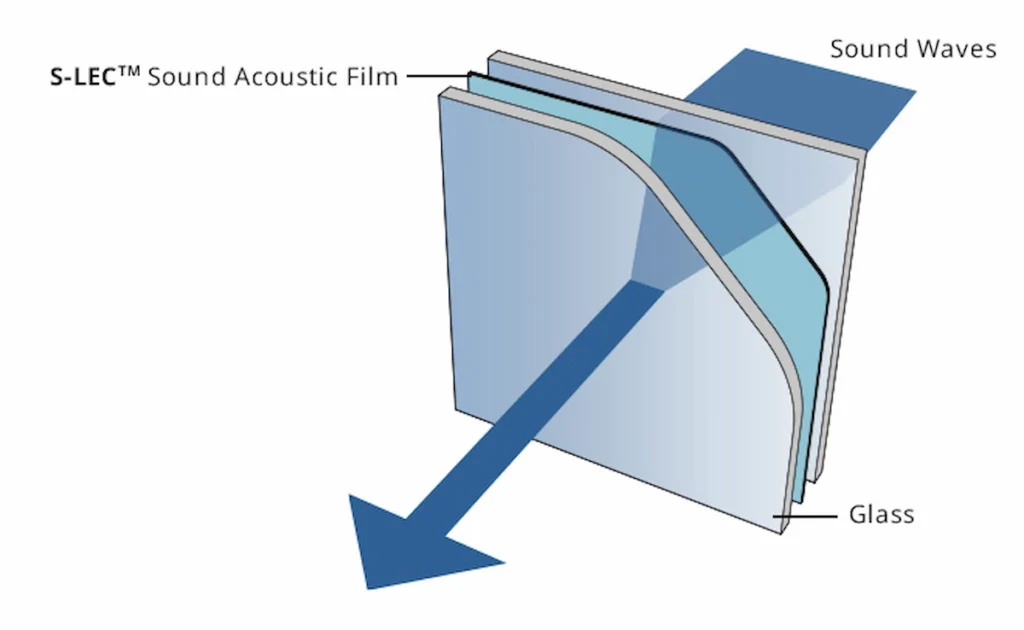

S-LEC™ Sound Acoustic Film, Acoustic PVB interlayer, for automotive laminated glass remarkably reduces the transmission of exterior noises, such as traffic, wind, and other disturbing sounds.

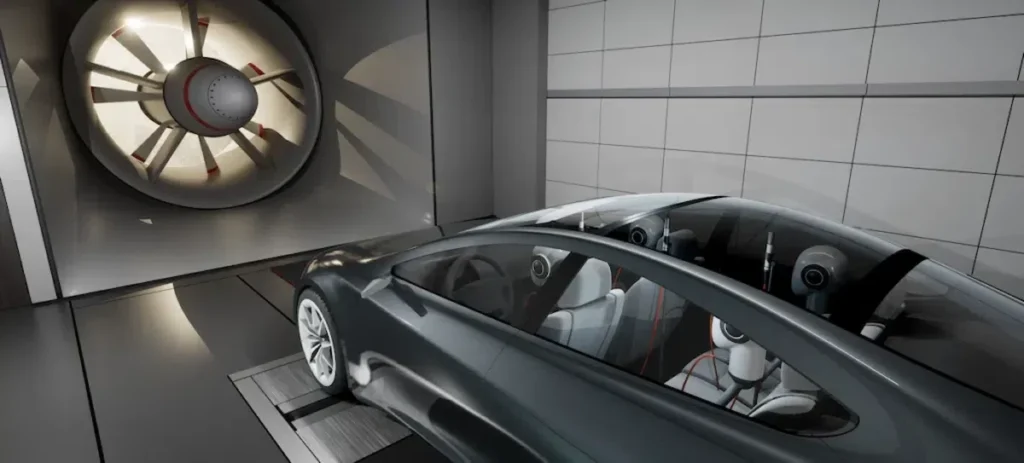

Noise in cabins is mainly caused by noise entering through the windshield and noise transmitted through the body of a vehicle, such as an engine, fans, and exhaust noise. There is, however, more to cabin noise than just noise transmitted from outside. In addition, pseudo-noise also impacts a vehicle’s noise reduction. Pseudo-noise is caused by air turbulence vibrations impacting vehicles’ windshield and windows. The turbulence is created as air passes over the hood, wipers, A-pillar, and side-view mirrors. Pseudo-noise can’t be assessed using Sound Transmission Loss (STL) testing, the most common test method to measure the extent to which sound energy is reduced as sound passes through certain materials.

Our NEW acoustic grade, SV grade, is developed to improve damping performance and significantly reduce noise caused by vibrations, which cannot be assessed through STL testing. Using the film in windshields and side windows can greatly enhance the cabin quietness and comfort, making driving a unique, luxurious experience.

Environmental conditions such as wind friction and raindrop create noise experienced inside a vehicle. The current trend for panoramic roof glass can intensify the noise level.

In the vehicle test at a wind tunnel, S-LEC™ Sound Acoustic Film shows an improvement in noise levels. The data shows an approximate 3dB improvement in sound pressure in the car, equivalent to a 3.7% improvement in articulation index(AI) compared to a roof glass without an acoustic PVB interlayer. The AI is used to quantify the ease of conversation inside the vehicle achieved by good sound insulation.

We are confident in our results and would happily share the details with you upon request. Please feel free to reach out to us for more information.

With global CO2 reduction targets, many car manufacturers are expanding their range of electric vehicles (EVs), and more startups have emerged.

On the other hand, it is said that the generation of EV-specific noise from the inverter and external noise, such as traffic noise, wind noise and raindrop noise, which the engine noise has masked, will become more noticeable. As external noise significantly impacts driver concentration and passenger comfort, there is a need for improved sound insulation in EVs.

Many car manufacturers and EV startups are introducing a concept where the glazing looks like one large window rather than separated glazing parts. It’s designed to appear as one extended piece of glass that runs from the windshield through the roof to the rear window. This design also allows more sunshine to enter the car and connects the occupants more with their surroundings.

When single-tempered or standard laminated glass is used for these vehicles, a lot of noise, such as road or wind noise, can be transmitted into the vehicle’s interior. By applying our acoustic PVB interlayer, S-LEC™ Sound Acoustic Film, these noises can be significantly reduced while maintaining the designer’s original intention of creating a luxurious vehicle cabin.

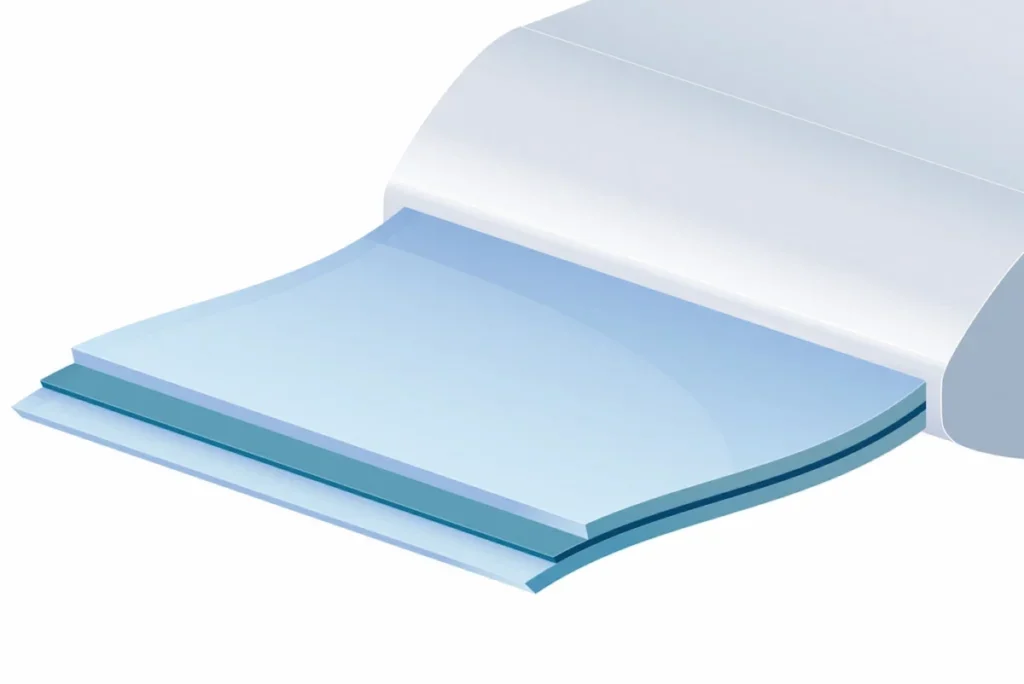

The high-quality sound insulation of the S-LEC™ Sound Acoustic Film lies in its multi-layer extrusion technology, where the acoustic PVB layer (core PVB layer) is placed between two PVB interlayer films (outside PVB layers). This method significantly improves the sound insulation performance while maintaining our standard interlayer’s essential benefits and thickness.

SEKISUI S-LEC is the world’s first to introduce sound insulation multi-layer technology and the industry leader in sound acoustic PVB interlayer films for automotive laminated glass, enhancing comfort for the majority of cars around the globe.

We offer the following combinations of multiple functions into one film:

S-LEC™ films are currently available in a wide range of standard colours and custom colour options with multiple Tvis (Visible Light Transmittance) to optimize various glass combinations according to a vehicle’s concept. Custom colour development is also possible.

S-LEC films are unique in their ability to offer a wide format gradient colour that transitions from 2% to >70% Visible Transmittance (Tvis), enhancing the exterior design and driver experience. Adapting to a windshield or rear window creates a feeling of openness and beauty through smooth gradation, providing an advanced design for automotive glass.

Laminated glass with S-LEC™ Solar Control Film blocks infrared and UV (ultraviolet) rays but allows visible light rays for optical clarity without blocking the electromagnetic transmissions necessary for mobile phone and sensor communication. Solar absorbing glass realized by S-LEC™ Solar Control Film protects people because the cabin or space stays cooler and your skin does not burn.

Experience a comfortable, efficient, connected, and safe environment.

S-LEC™ Wedge-shaped Film enables highly focussed, visibly clear HUD images for a seamless driving experience.